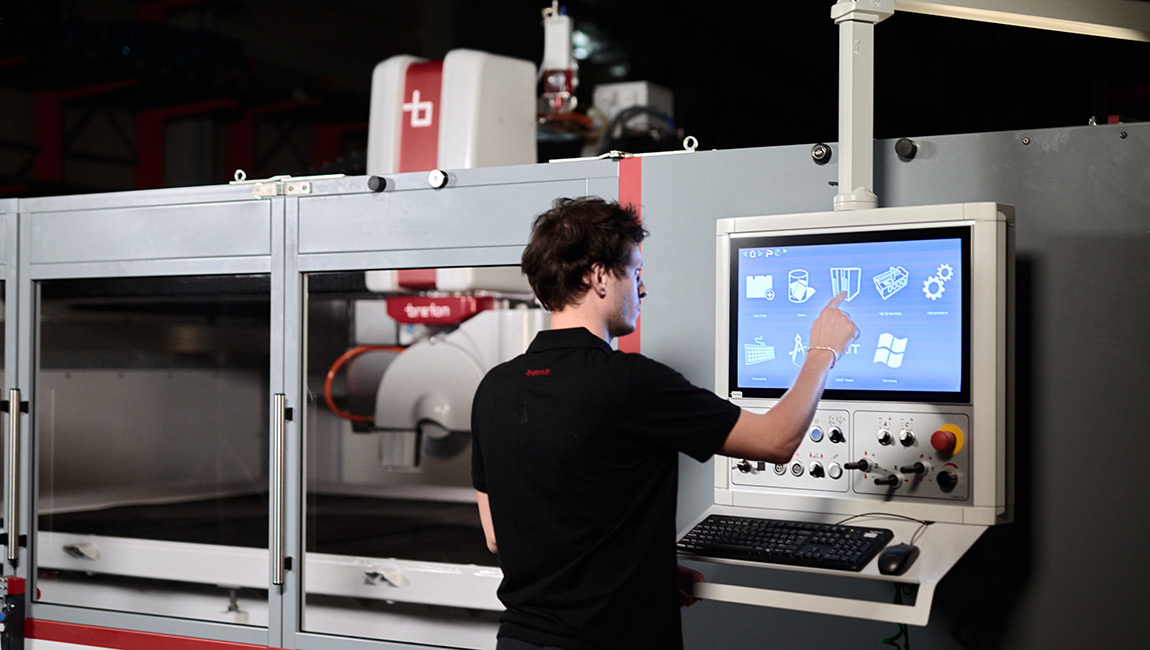

Combi is delivered pre-assembled with prewired electrical cabinet. The entire assembly and start-up phase can be completed in 5 days. Combi can be easily relocated on the customer's site to accommodate possible changes to the production layout.

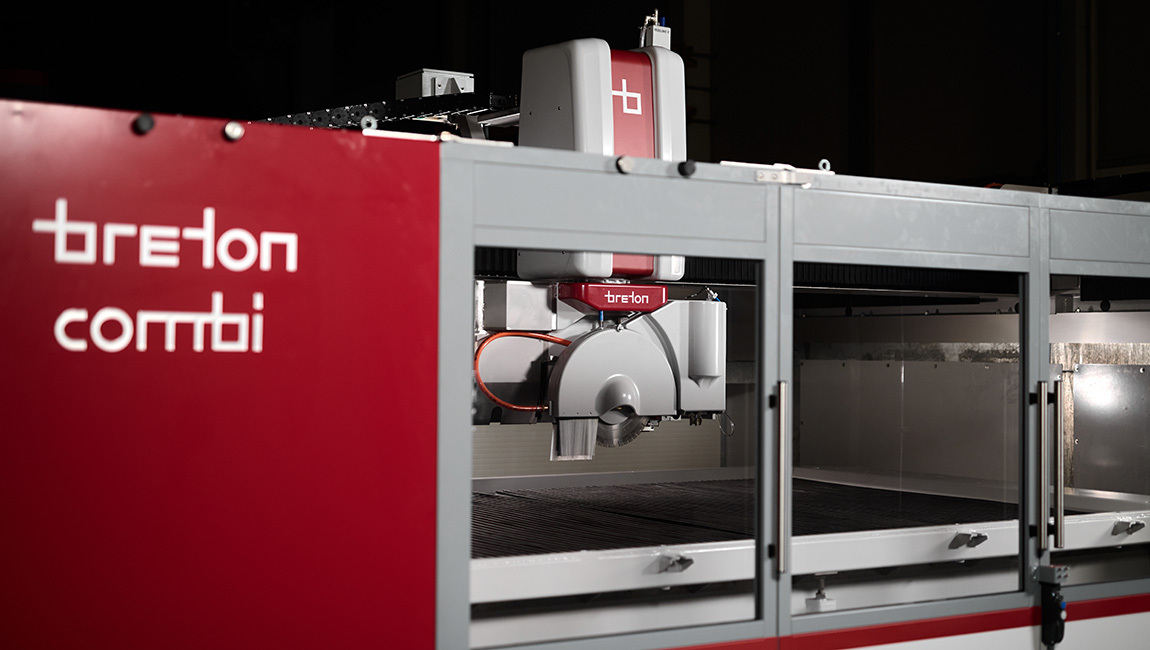

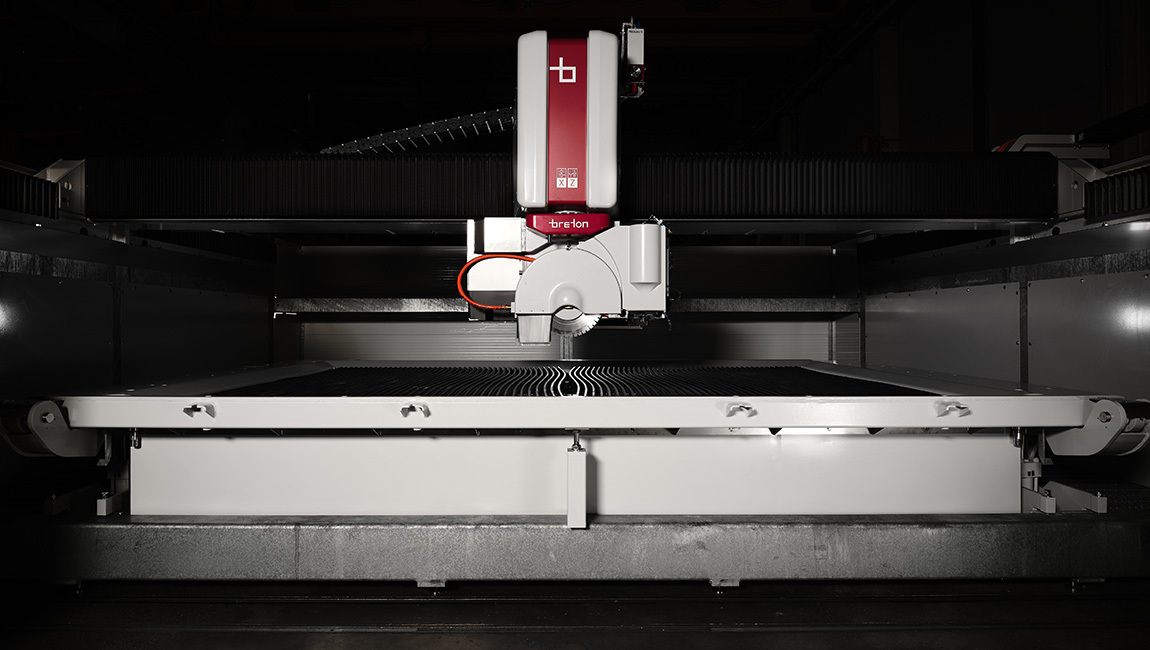

Monobloc 5 axis disc milling and cutting centre combined with a waterjet cutting system

The possibility of combining disc cutting processes with waterjet cutting, together with elements such as on-board spindle vacuum cups, bridge camera and tilting table, make Combi the most advanced cutting centre for the creation of kitchen tops, vanity tops and claddings.

Breton Combi

Reasons why

The robustness and versatility that were lacking

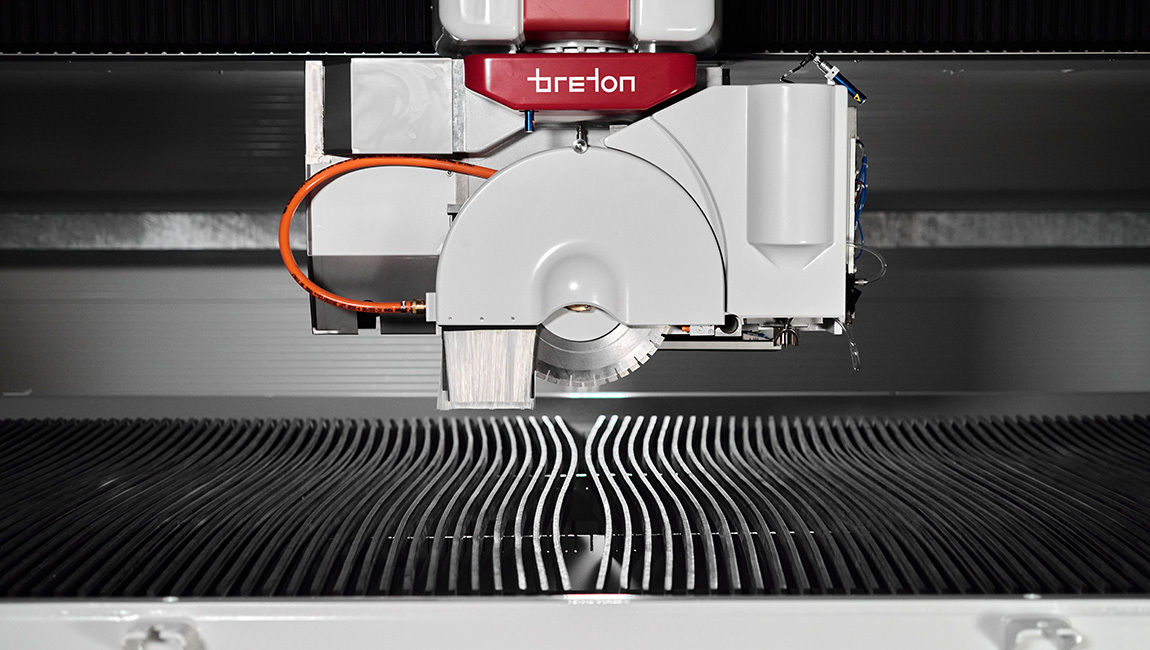

Combi’s strength is that it makes it possible to use disc cutting and waterjet cutting without having to move the slab and to choose the best technology in terms of efficiency, depending on the operation to be performed. The machine will therefore opt for disc cutting, more economical, when possible, and switch to waterjet technology in all other cases. This serves to minimise the production of scrap and execute work processes more in less time and hence at lower cost. It is also possible to create inclined planes without having to mill the workpiece surface but merely by exploiting variable angle waterjet cutting with continuous touch probing performed by the Miterwave Touch system.

Major advantages for higher productivity also derive from the spindle on-board vacuum cups that make it possible to move the pieces to use the disc cutting function. In addition, installing the Rocket Tool system – an additional motor spindle that can reach up to 14,000 rpm, on which to mount end cutters or core drill bits – allows the execution of through holes, blind holes, milled recesses and rebates.