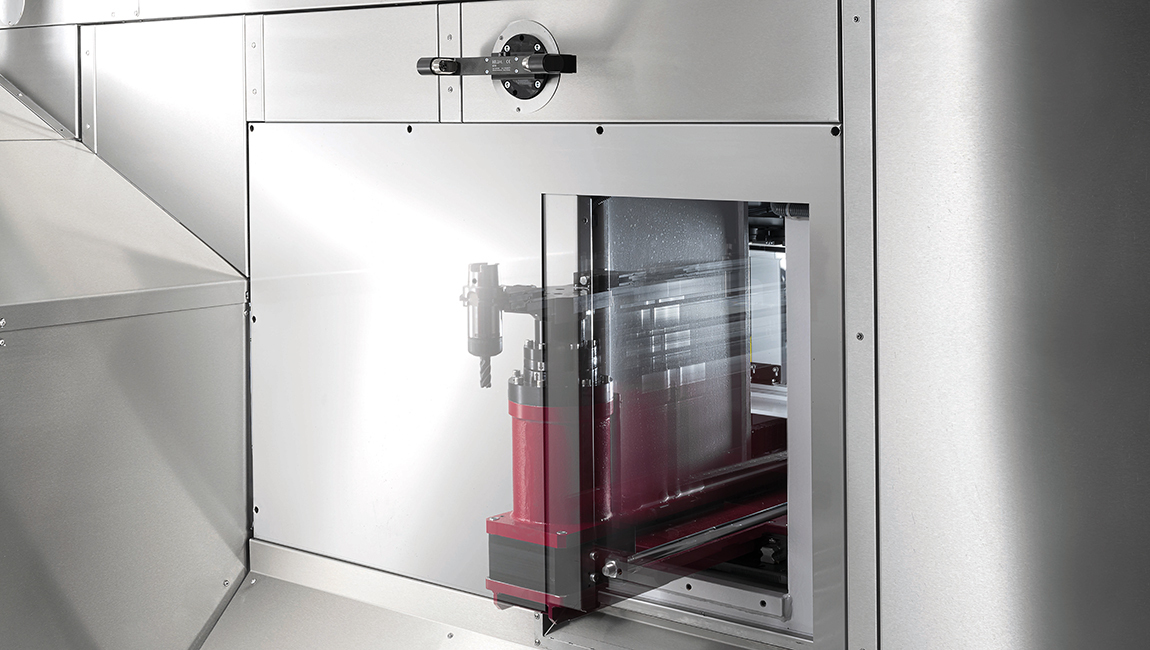

For axis movements we use direct drive motors, which allow us to eliminate backlash and vibration sometimes caused by the deflection belts and obtain a greatly superior dynamic response.

Removing drive belts also eliminates “noise”, making it possible to achieve superior finishing quality, even on the most complex surfaces.

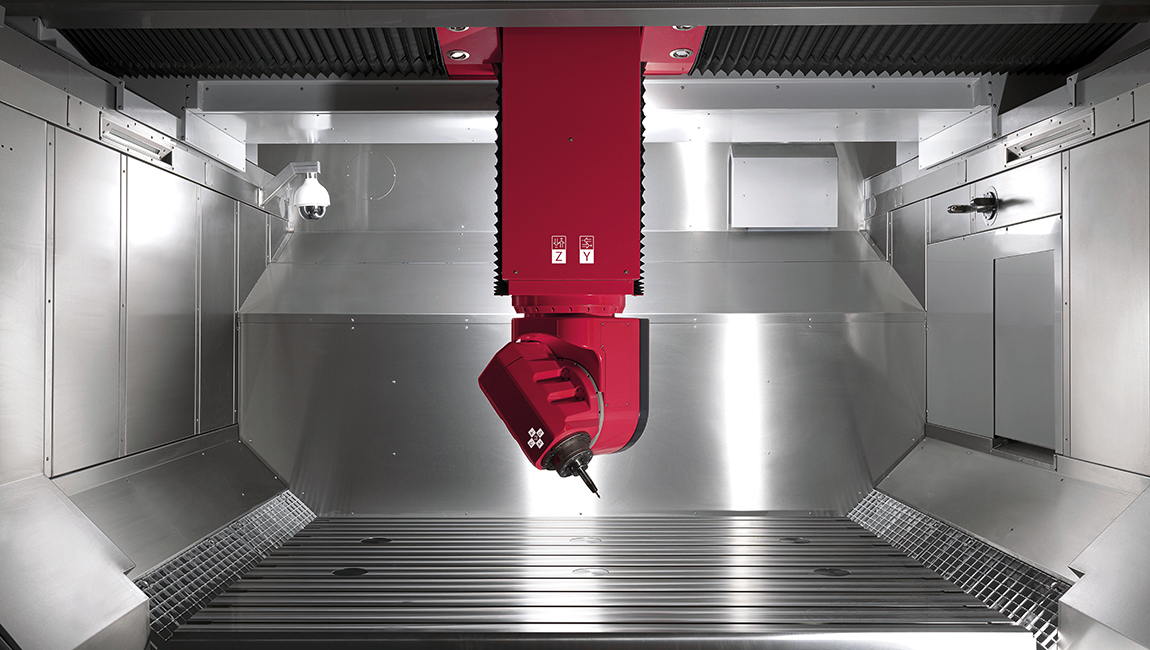

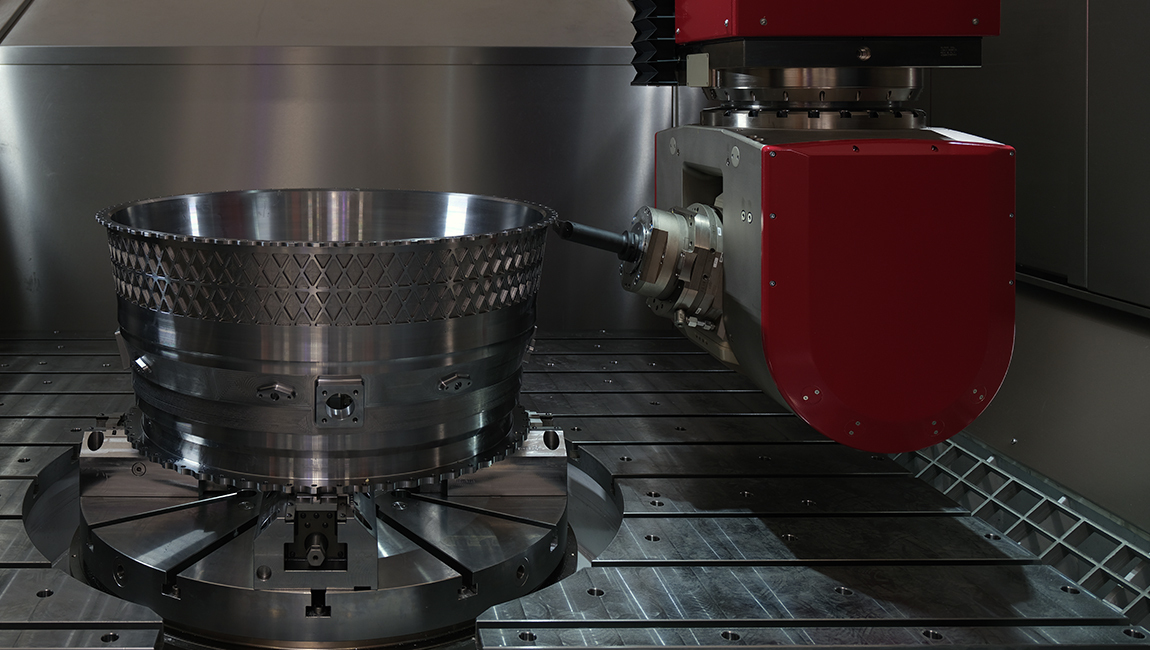

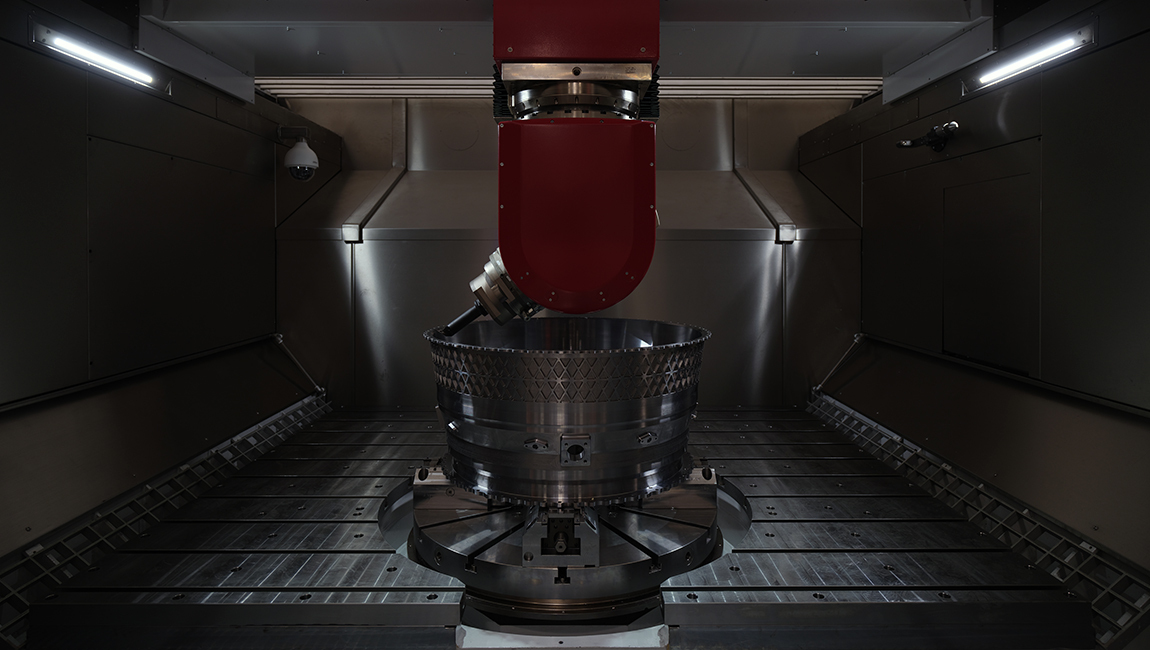

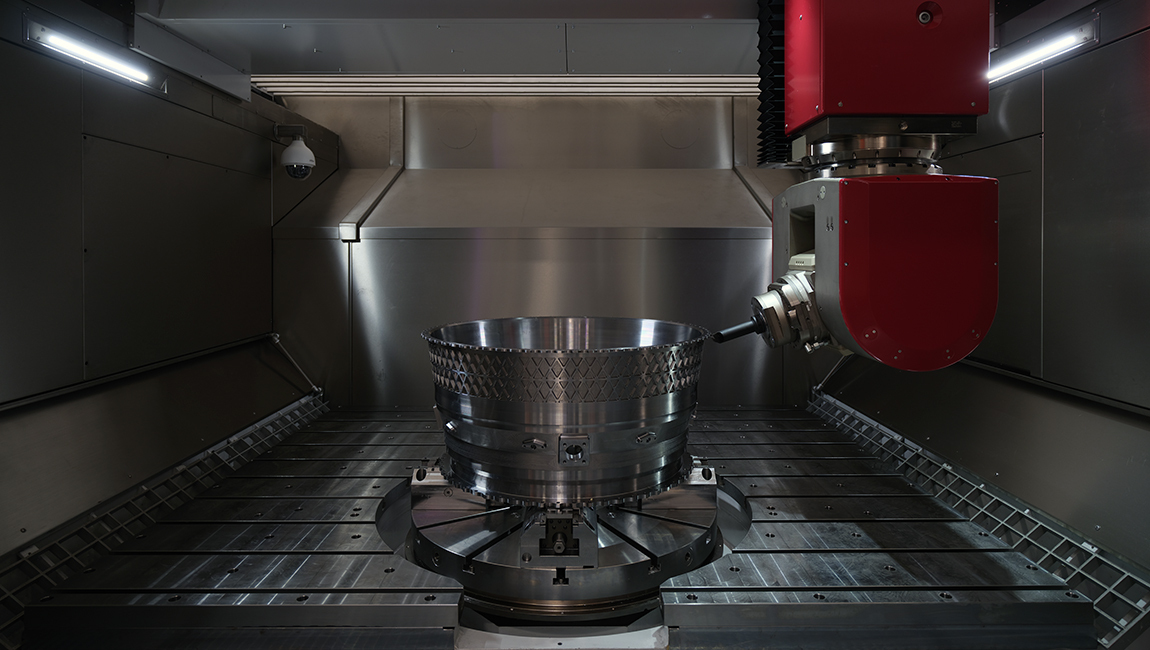

High dynamic and high precision 5 axis monobloc vertical gantry machining centre

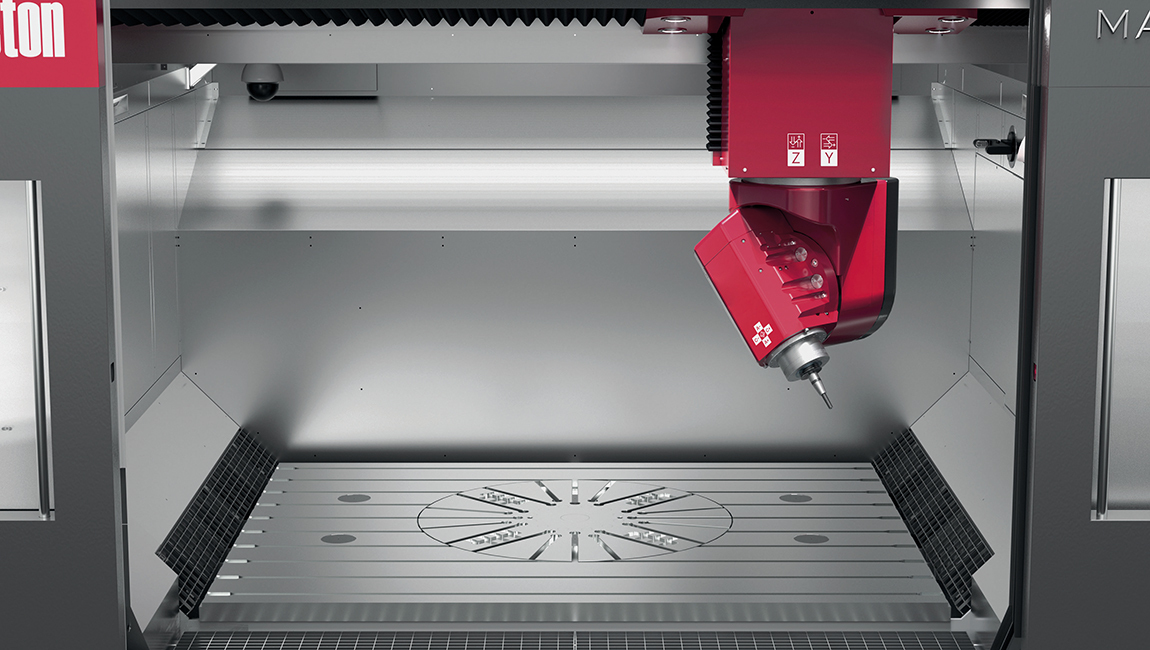

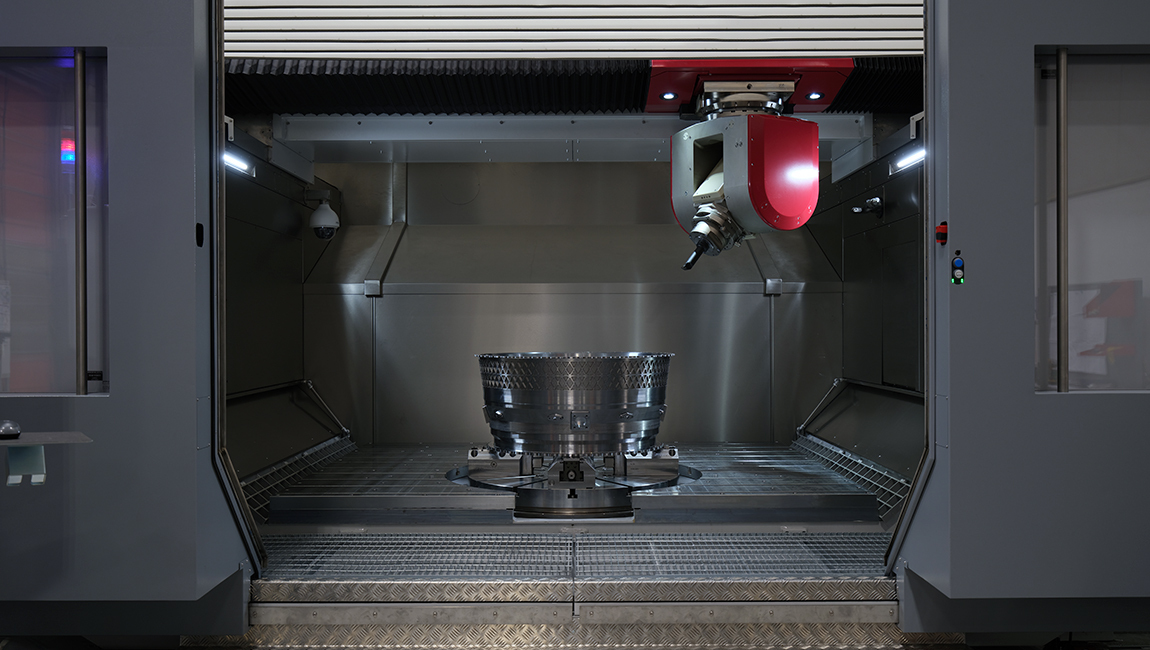

Available in various configurations to provide a perfect answer to the needs of specific applications, including moulds and dies, aerostructures, and composite materials machining. This machine is ideal for hi-feed roughing, semi-finishing and finishing of medium-size workpieces in steel, lightweight alloy or special composites.

Breton Matrix E1

Reasons why

A host of advantages with a monobloc machining centre

Matrix E1 stands out due to its rigid monobloc structure in arc welded steel designed to guarantee robustness and to damp possible vibrations during the heaviest duty machining work. Given the absence of mating surfaces between columns and work table, reworking and adjustment phases have been eliminated.

The chip evacuation augers incorporated in the structure can be replaced with dust suction systems for machining of composite materials. Bridge and RAM among the most robust in their category: this guarantees stability in roughing work while maintaining high dynamics and accuracy in finishing work.

The direct motors on all linear axes improve precision and dynamic, thus eliminating backlash and vibration caused by drive belts. The control of thermal expansions is guaranteed by the thermo-symmetrical structure and by Thermal Shield, improving both precision and repeatibility over time.

Breton Matrix E1 arrives already assembled and can be installed on flat foundations, which reduces installation time and costs.

Materials

Processes

Industries

Technologies

Numerical control

Technological highlights

Other versions of Breton Matrix E1

Version comparative table

| Matrix E1 800 K20 | Matrix E1 1000 K20 | |

|---|---|---|

"X" axis travel | 2000 mm | 2000 mm |

"Y" axis travel | 2500 mm | 2500 mm |

"Z" axis travel | 800 mm | 1000 mm |

"X" axis rapid feed rate | 50 m/min | 50 m/min |

"Y" axis rapid feed rate | 50 m/min | 50 m/min |

"Z" axis rapid feed rate | 40 m/min | 40 m/min |

"A" axis travel | -105 - 120 ° | -105 - 120 ° |

"A" axis rapid speed | 30 rpm | 30 rpm |

"C" axis travel (RANGE) | -305 - 305 ° | -305 - 305 ° |

"C" axis rapid speed | 30 rpm | 30 rpm |

Tool taper type | HSK-A63 | HSK-A63 |

Dimensions of the workbench (length) | 2000 mm | 2500 mm |

Dimensions of the workbench (width) | 1000 mm | 1000 mm |