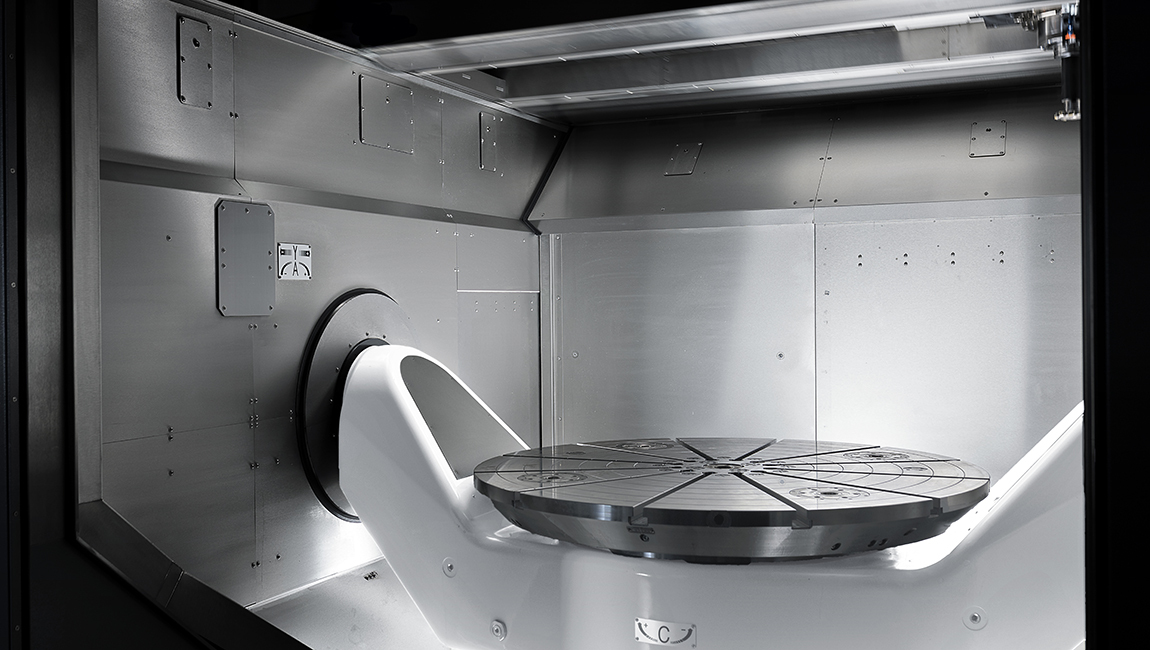

The machine is equipped with a series of high performance trunnion tables with Direct Drive technology.

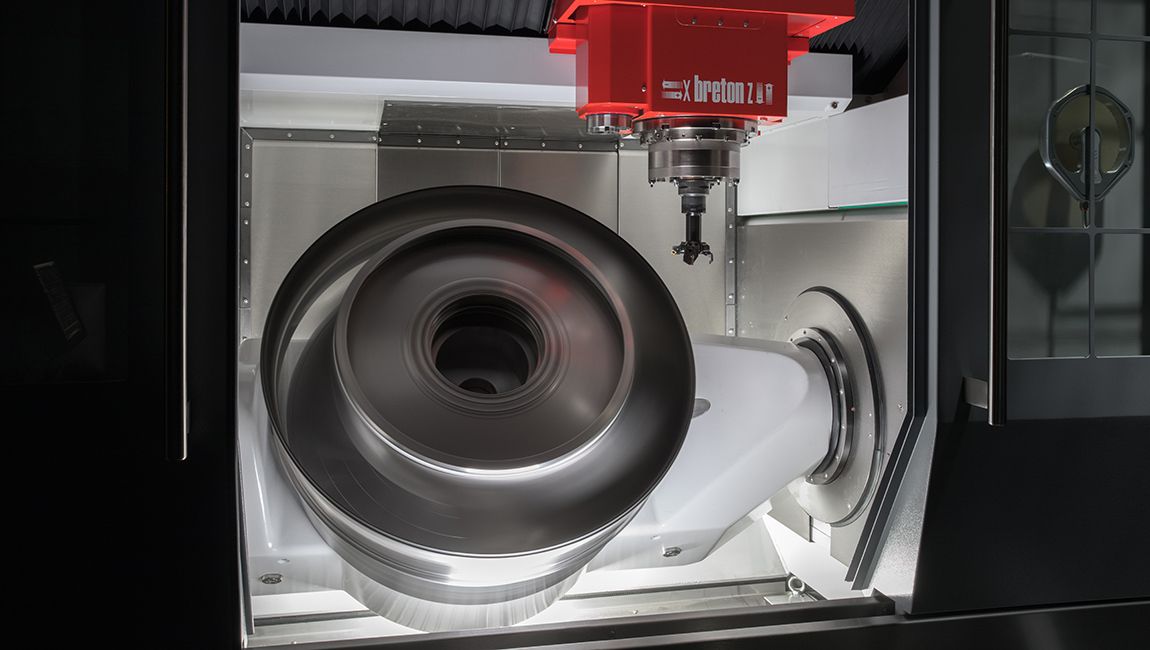

5 axis vertical machining centre with trunnion table for milling and turning with high power and high precision

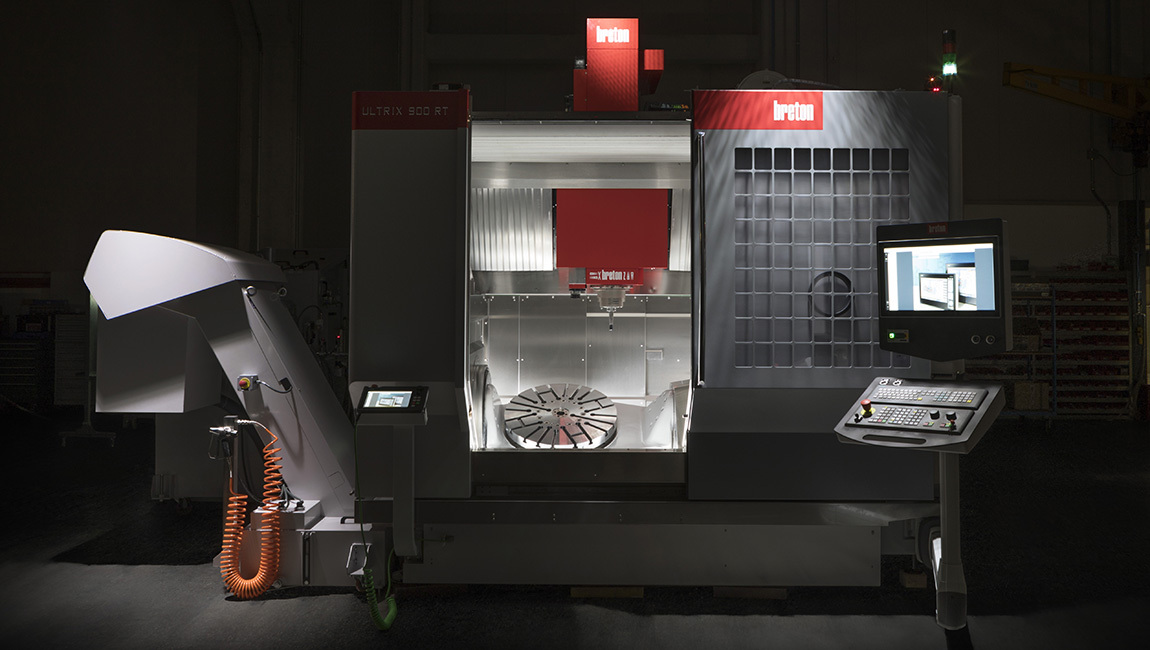

A robust and stable Metalquartz base frame and a dedicated boring bar for a full range of operations on a single machining centre. Ideal for roughing, semi-finishing and finishing operations on superalloys, steel, lightweight alloy, or composites.

Breton Ultrix

Reasons why

Multitasking to have all work phases performed on a single machine

The Breton Ultrix series is ideal for milling and turning of medium-size/large workpieces in titanium, superalloys, steel, lightweight alloys, and special composites. Developed on gantry architecture with a gantry type moving bridge, the machine has a trunnion table and independent boring bar.

A machining centre for high speed milling and turning that delivers high performance with absolute precision while also being able to handle large size workpieces. With strokes of up to 1,700 x 1,700 x 1,000 mm and maximum swing diameter over the bed of 1,600 mm, the Ultrix E3 is our largest trunnion table machine. Painstaking attention was awarded to the layout during the design stage, with the aim of achieving the smallest possible machine footprint.Ultrix is the best solution for machining aero engine components: the vertical spindle facilitates workpiece positioning, the trunnion table gives better access and allows the part to be cleaned with ease and removal of chips by rotating the A axis.

Up to two angle heads can be housed at the rear of the machine, with fully automatic loading and unloading cycles. The head body is clamped hydraulically to the RAM to allow transmission of all the available motor spindle torque.

The top bellows open completely, facilitating workpiece loading/unloading operations with overhead cranes. The work area is fully clad in stainless steel to make it bright, easy to clean, and impervious to erosion caused by machining chips. All the axes are pressurised to prevent infiltration of contaminants. Accessibility has been significantly improved, allowing the operator within just 15 cm of the turning table.

Materials

Processes

Industries

Applications

Technologies

Numerical control

Patents

Technological highlights

Other versions of Breton Ultrix

Version comparative table

| Ultrix E2 | Ultrix E3 | Ultrix E3 HD | |

|---|---|---|---|

"X" axis travel | 1150 mm | 1700 mm | 1700 mm |

"Y" axis travel | 1000 mm | 1600 mm | 1600 mm |

"Z" axis travel | 700 mm | 1000 mm | 1000 mm |

"X" axis rapid feed rate | 60 m/min | 50 m/min | 50 m/min |

"Y" axis rapid feed rate | 60 m/min | 50 m/min | 50 m/min |

"Z" axis rapid feed rate | 40 m/min | 50 m/min | 50 m/min |

"A" axis travel | -30 - 120 ° | -120 - 120 ° | -120 - 120 ° |

"C" axis travel | Illimitato | Illlimitato | Illimitato |

"A" axis rapid speed | 50 rpm | 30 rpm | 50 rpm |

"C" axis rapid speed | 100 rpm | 60 rpm | 100 rpm |

Rotary table Speed S6 | 500 rpm | 500 rpm | 450 rpm |

Max. torque in S6 | 2700 Nm | 2700 Nm | 4200 Nm |

Turning bar stroke | 225 mm | 450 mm | 450 mm |

Tool taper type | Capto C8 | Capto C8 | HSK-T100 |

Rotary table diameter | 1250 mm | 1000 mm | 1200 mm |

Rotary Table Payload | 1500 kg | 2500 kg | 2500 kg |

"T" slot size | 22 mm | 22 mm | 22 mm |