Linked to the main motor to transmit all the necessary power and, with its 1000 mm diameter, ideal to avoid stressing the wire.

Multiwire machine for sawing stone blocks

Multi diamond wire machine to saw slabs in thicknesses of 20 mm, 30 mm, or more.

The structural robustness combined with the characteristic triangle system makes it possible to saw marble and granite blocks to make slabs of various thicknesses.

Breton Paragon

Reasons why

The new generation triangle solution

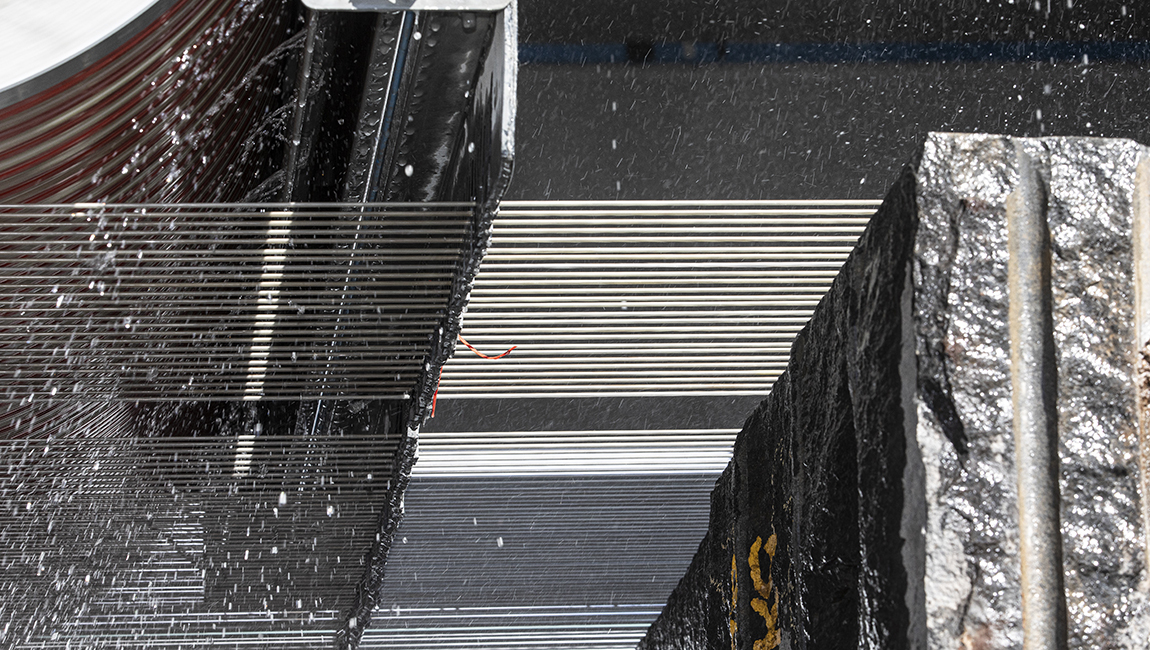

Paragon was designed to minimise vibration during the cutting phase and guarantee the maximum precision in wire positioning in order to minimise wastage of material.

The isosceles triangle construction geometry, combined with the one metre diameter rollers, make it possible to optimise efficiency of the wire in contact with the material or in the free sections, reducing while also guaranteeing very high traction. The system with 5 rotary units is composed of the tension wheels unit, 2 low guide wheels, the drive wheel and the idle wheels set.

The high performance of the machine has tangible results in terms of production, wire lifetime, and maintenance of cutting positions. Also, with the “adjustable guide wheels”, also with small blocks, you can always use the machine in the best conditions in terms of the tangential direction of sawing.

Wheel width from 1000 to 2100

Wire diameters ranging from 5.3 to 7.3 mm

Number of available wires: from 31 to 78

Max. block length: 3.750 mm

Max. block width: 2.200 mm

Materials

Processes

Industries

Technological highlights

Other versions of Breton Paragon

Version comparative table

| MULTIWIRE PARAGON P 1000/5/V/42 | MULTIWIRE PARAGON P 1000/6/V/41 | MULTIWIRE PARAGON P 1600/5/V/60 | MULTIWIRE PARAGON P 1600/6/V/59 | MULTIWIRE PARAGON P 2100/5/V/78 | MULTIWIRE PARAGON P 2100/6/V/76 | |

|---|---|---|---|---|---|---|

Max. dimensions of the block (length) | 3700 mm | 3700 mm | 3700 mm | 3700 mm | 3700 mm | 3700 mm |

Max. dimensions of the block (height) | 2200 mm | 2200 mm | 2200 mm | 2200 mm | 2200 mm | 2200 mm |

Obtainable slab thickness for 20 mm sawing (new wire) | 21 - 21.2 mm | 20.6 - 20.8 mm | 21 - 21.2 mm | 20.6 - 20.8 mm | 21 - 21.2 mm | 20.6 - 20.8 mm |

Obtainable slab thickness for 30 mm sawing (new wire) | 30.1 - 30.3 mm | 29.9 - 30.1 mm | 30.1 - 30.3 mm | 29.9 - 30.1 mm | 30.1 - 30.3 mm | 29.9 - 30.1 mm |

Max. number of wires for sawing 20 mm thickness | 42 | 41 | 60 | 59 | 78 | 76 |

Max. number of wires for sawing 30 mm thickness | 31 | 30 | 45 | 44 | 58 | 57 |

Diameter of the diamond wire (new wire) | 5.3 - 5.5 mm | 6.3 - 6.5 mm | 5.3 - 5.5 mm | 6.3 - 6.5 mm | 5.3 - 5.5 mm | 6.3 - 6.5 mm |

Wire-driving groove pitch | 9.1 mm | 9.3 mm | 9.1 mm | 9.3 mm | 9.1 mm | 9.3 mm |

Weight | 40000 kg | 40000 kg | 52000 kg | 52000 kg | 52000 kg | 52000 kg |

Overall dimensions (length) | 10400 mm | 10400 mm | 10400 mm | 10400 mm | 10400 mm | 10400 mm |

Overall dimensions (width) | 5450 mm | 5450 mm | 6800 mm | 6800 mm | 6800 mm | 6800 mm |

Overall dimensions (max height when starting to cut) | 7600 mm | 7600 mm | 7600 mm | 7600 mm | 7600 mm | 7600 mm |

Overall dimensions (max height when finishing to cut) | 6200 mm | 6200 mm | 6200 mm | 6200 mm | 6200 mm | 6200 mm |