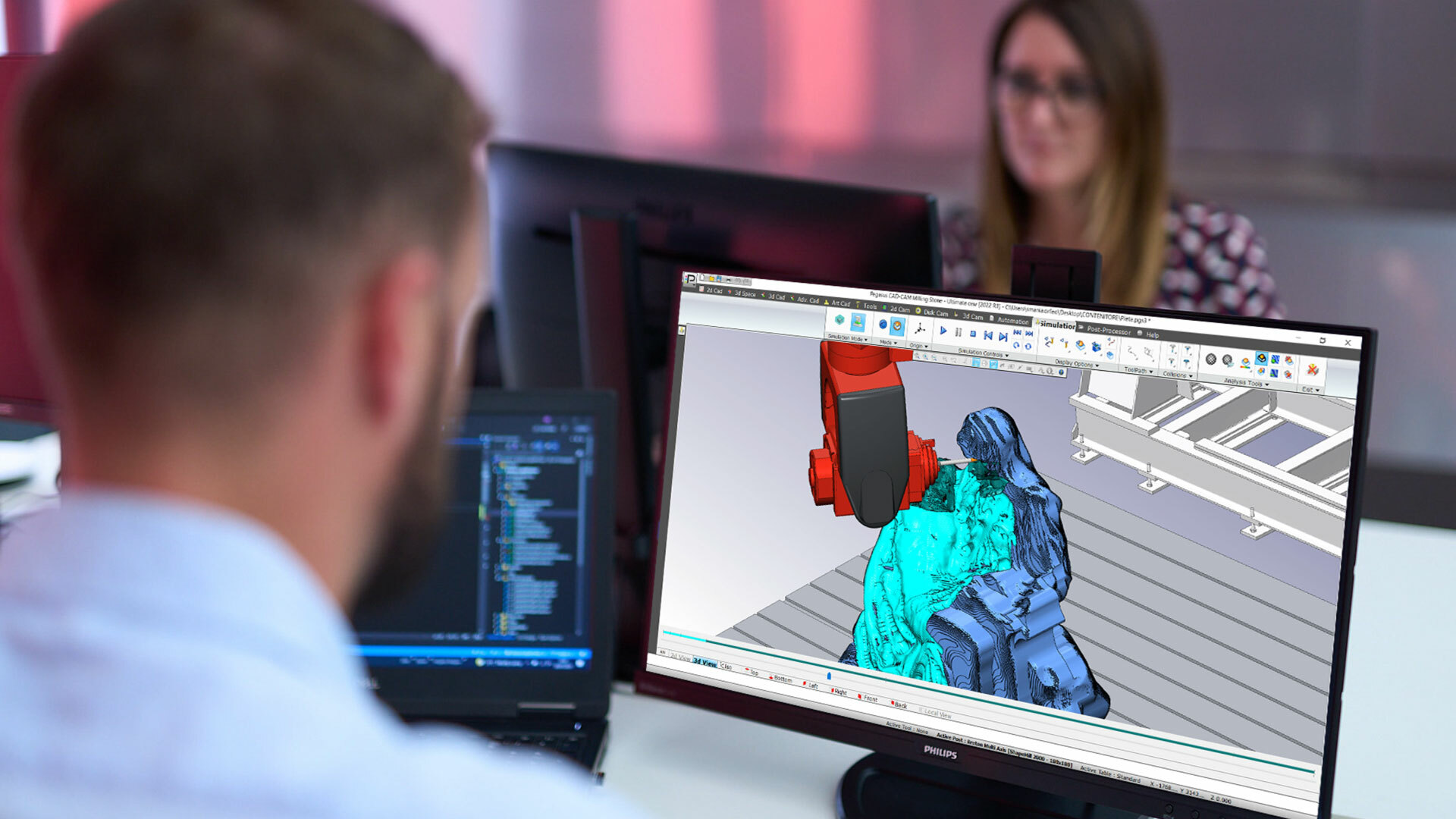

The CAD/CAM software suite dedicated to NC machining centres for stone processing

Breton Maestro is the dedicated proprietary software suite for numerically controlled contouring and shaping centres, conceived and developed for advanced management of the production of countertops, blocks or complex sculptural artworks.

Breton Maestro

Reasons why

The suite that can be adapted to fit specific machining environments

Dedicated versions and modules

The Breton Maestro suite is available in different versions and modules dedicated to specific work environments.

According to the number of interpolated axes of the machining centre, the type of tool and the processes to be performed, you can choose the Breton Maestro version that best fits your needs.

Materials

Mineral surface resin based

Marble

Granite

Ceramic

Terrazzo